Grubbens, part of the Cellwood group, can offer a range of specially designed pulpers to meet your process needs, whether you require a complete new system or a bespoke upgrade. Grubbens pulpers boast low energy consumption, low maintenance costs and high pulping consistency. This is as well as having the capability to disintegrate pulp gently, without the use of chemical additives or steam with wet-strength material.

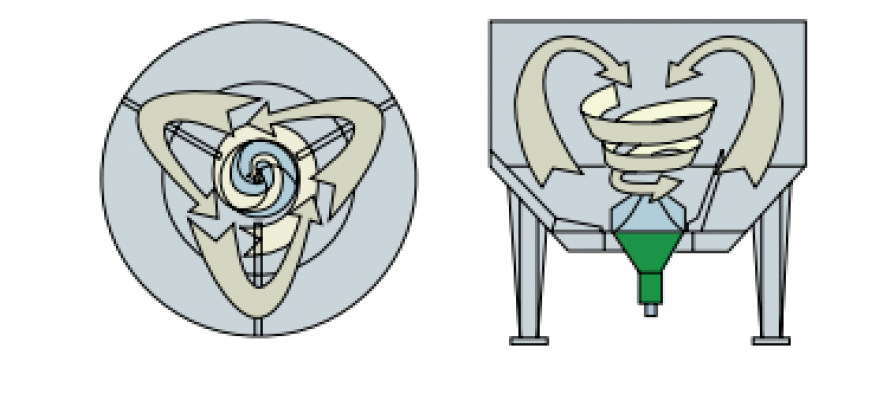

Pulpers can be installed either horizontally or vertically and can operate at low (3-5%), medium (5-9%) or high (12-19%) consistencies. Grubbens specially designed rotors can be optimised for a number of different needs and applications, and have the same design for both vertical and horizontal pulpers. For example the S-Rotor is adapted for high pulp consistency, low energy consumption and mechanical processing. Vertical pulpers can be used for both batch and continuous operation. Continuous operation requires a slightly lower operating consistency, but the shorter retention time results in much higher capacity in the same volume.

Operation:

Grubbens pulper units are designed for use with either a belt drive or a gear drive. As the rotor unit has its own bearings, when using a gear drive, the coupling is connected to the rotor shaft. This means that the gear only has to sustain torque forces. A belt drive provides quieter operation and increased flexibility, while a gear drive is used when higher power demand is required.

Features and Benefits:

- Low power consumption

- Rotor units have the same design for both vertical- and horizontal pulpers

- Rotor units can be equipped with extra details when used for wet strength material

- The design of the rotor enables the strainer holes to be cylindrical which makes the strainer plate turn-able and gives it a longer life time

- Pulper tub can be built to fit into existing or new buildings

- Vertical pulpers can be operated both in batch- and continuous mode. In batch mode up to 9% and continuous up to 7% in operating consistency

- UTM pulpers can be operated up to 5 - 6% in continuous mode

- High consistency pulpers are always operating in batch mode. This pulper has no strainer plate, strainer plate is in the reject separator