Full Paper, Waste and Other Industries Product List

Browse our full product list to see the vast range of products we provide for varying different industries.

ACP

A select range of parts and spares are available for ACP series Andritz* pumps, including impellers and front insert.

READ MORE »AH-Range

Pattern parts and spares for a branded slurry pumps range, known as AH*-series pumps. These come with the same guarantees and warranties as the OEM.

READ MORE »APP

Directly interchangeable parts for Sulzer* APP pumps are possibly the most popular range of equivalent parts and spares. L&M, through Salvtech*, can provide a full catalogue of spares for the Sulzer* APP pump range.

READ MORE »ASP

Another popular model within L&M’s equivalent spares for Sulzer* pumps, is spares for ASP pumps. This includes pattern spare parts for Ahlström* ASP pumps, as this brand name was incorporated into the Sulzer* group.

READ MORE »DEA 1

Pressure Boosting System for 1 pump. Ideal for the pumping of clean and cold water for pressure boosting in residential buildings, industrial operations and municipal water supply.

READ MORE »DEA 2-6

The DEA 2-6 is a pressure boosting system for use with 2 - 6 pumps.Ideal for the pumping of clean and cold water for pressure boosting in residential buildings, industrial operations and municipal water supply.

READ MORE »EXTRAIR

The EXTRAIR centrifugal pump is a vertical pump, ideally suited for conveying solid bearing medium out of vacuumed basins. It can be used in a number of different industrial processes.

READ MORE »GH and GV

Multistage high-pressure centrifugal pump with selfpriming and non-selfpriming options. Ideal for use in the chemical and food industry as well as metal processing mills and general process plants.

READ MORE »GR

Pattern parts and spares for Warman GR series pumps. These come with the same guarantees and warranties as the OEM.

READ MORE »HWL Automatic Domestic Water System

The HWL automatic domestic water system is made up of a horizontal pressure tank with a double acting piston pump with crank shaft built on top. Ideally suited for drinking, fresh and rainwater in domestic water supply. The system is ready assembled.

READ MORE »HWL-G Automatic Domestic Water System

The HW-LG automatic domestic water system is made up of a horizontal pressure tank with a double acting piston pump with twin-gear drive built on top. This system is ready assembled and is ideally suited for drinking, fresh and rainwater in domestic water supply, but can however also be used in general industry and agricultural processes.

READ MORE »ISO

A select range of pattern parts and spares are available for ISO series Andritz * pumps.

READ MORE »LM HS

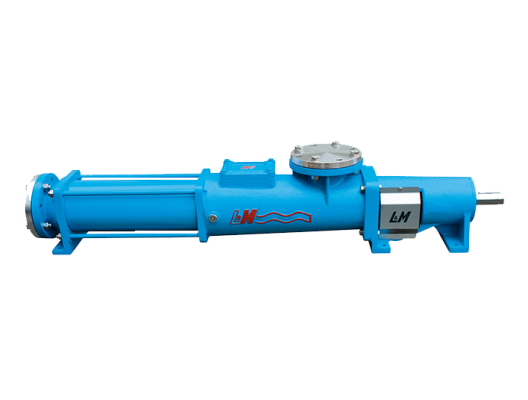

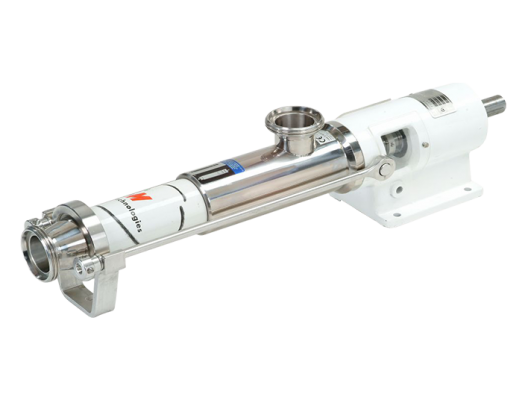

The pump series LM-HS has been designed to get a positive displacement pump, with a helical rotor, to decant viscous liquids with or without solids in suspension. Suitable for the waste water, chemical, cosmetic, pharmaceutical and food industries, as well as many others.

READ MORE »LM HS CIP

The LMHS CIP is a positive displacement pump with helical rotor, designed to decant viscous liquids. Ideal for the pumping of sludge, in the process and disposal of this material, in sewage treatment plants. This pump can be used for the pumping of highly viscous sludges, with a high solid content and dry matter fractions, as well as gas containing sludges.

READ MORE »LMS ANR

Horizontal pumps according ISO 2858 (DIN 24256) for the Pulp & Paper and Chemical Industry.

READ MORE »LMS SPR

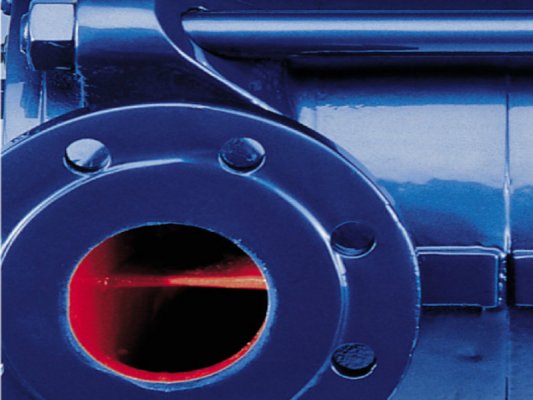

Horizontal degassing centrifugal pump for a number of different applications and industrial processes.

READ MORE »MHC and MVC

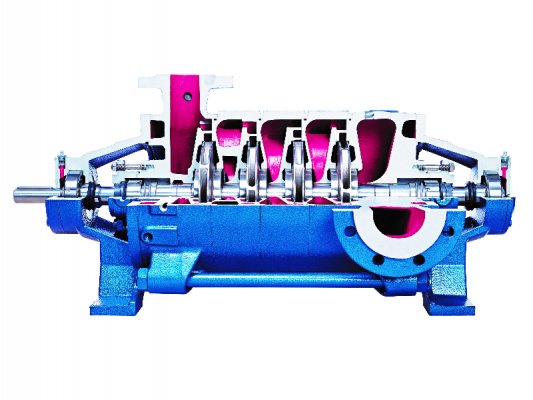

High pressure, multistage centrifugal pumps suitable for shipbuilding and mining industries, as well as the chemical and petrochemical industry. Also suitable for pressure boosting systems, central heating, cold and hot water circulation, water supply systems and power stations

READ MORE »NB

A select range of equivalent parts and spares can be provided for SCAN* NB series pumps

READ MORE »NMH and NMV

Non-selfpriming, multistage, high-pressure centrifugal pumps in either a vertical (NMV) or horizontal (NMH) design. For pumping clear or slightly contaminated liquids in pressure boosting systems, central heating, cold and hot water circulation, water supply systems, shipbuilding, the mining industry, power stations, filter units, fire extinguishing and irrigation plants.

READ MORE »NMVN & GVN

The NMVN and GVN Vertical Immersed Pumps are high pressure multistage pumps. Possible with both a wet and dry installation, these pumps are ideal for a number of different processes and industries.

READ MORE »NPP

Equivalent Sulzer* NPP spares and parts including pattern Ahlström* NPP spares, especially impellers, shafts, side plates and other parts. These parts are manufactured in Duplex Stainless Steel and offer the same warranty as guarantees as the OEM.

READ MORE »S Series

A full range of equivalent parts and spares are available for the S series Andritz* pumps.

READ MORE »SVN & SKVN

The SVN and SKVN Vertical Immersed Pumps, are low pressure pumps, that are usually constructed as a single stage pump. These pumps are ideal for many industry applications, with some of the more popular uses for this pump being in sewage and refinery processes.

READ MORE »UP-B4

The UP-B4 is designed for pumping liquids is wells or spaces at a minimum of 4” in diameter. The pump diameter is made to a maximum of 100 mm. Maximum temperature up to + 30°C.

READ MORE »UP-B6 and UP-B12

The UP-B6 to UP-B12 are designed for pumping liquids is wells or spaces at a minimum of 6” – 12” in diameter, depending on pump type. Maximum temperature up to + 80°C.

READ MORE »